To begin with, it is necessary to distinguish between cold plasma and hot plasma. Plasma is the fourth state of matter which is made of ionized gas with free electrons and ions. Plasma also contains neutral particles. In a cold plasma there is a state of non-equilibrium where the electrons are at high temperature of thousands of degrees, whereas the ions are at room temperatures. This could be possible if a dielectric surface is placed between the two electrodes such as in Dielectric Barrier Discharge (DBD) configuration. In a hot plasma, there is equilibrium between the electrons and ions and they are both at high temperatures of thousands of degrees. Cold plasma has applications in surface cleaning and treatment and hot plasma has applications in industrial applications and fusion research. More specific applications of cold plasma are in industries such as automotive, packaging, textile and food processing where one can do surface cleaning, activation and sterilization [Reference 1]. On the other hand, more specific applications of hot plasma are in industries such as metal cutting, welding and waste treatment where temperatures of thousands of degrees are needed [Reference 1].

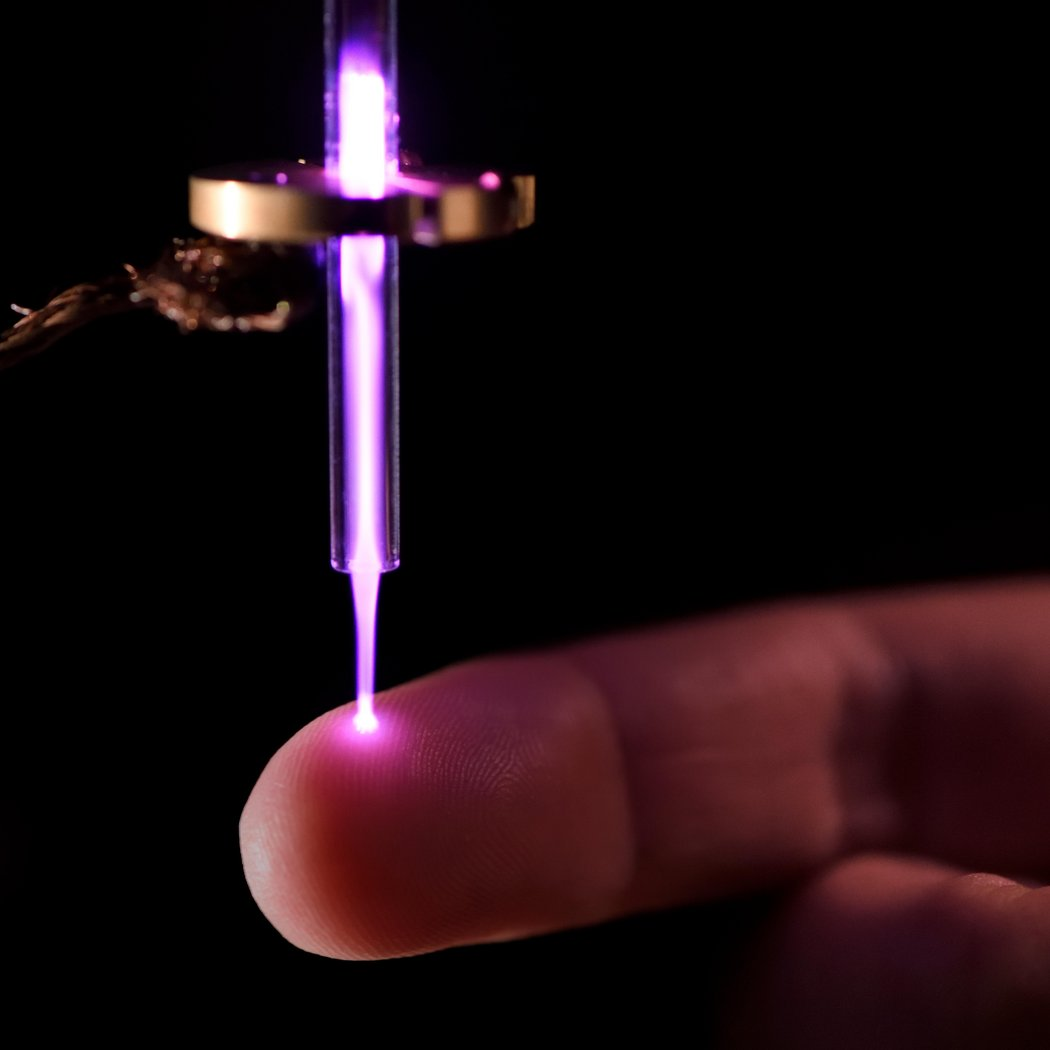

Shown in the figure below is a cold plasma (Plasma jet) depiction and one can see that the plasma exposure is not burning the finger.

Figure 1: Plasma jet is an example of cold plasma [Reference 2]

One also has to distinguish between low pressure plasma which requires a vacuum chamber and atmospheric pressure plasma which operates at atmospheric pressure as its name implies.

Each plasma type has its own pros and cons. The low-pressure plasma’s requirement for a vacuum chamber makes it more expensive and difficult to operate, but the generated plasma has more uniformity and has a wider spread. The atmospheric pressure plasma is more versatile and less expensive, but the plasma is not uniform and its spread is lower. In this article we focus on atmospheric pressure cold plasma.

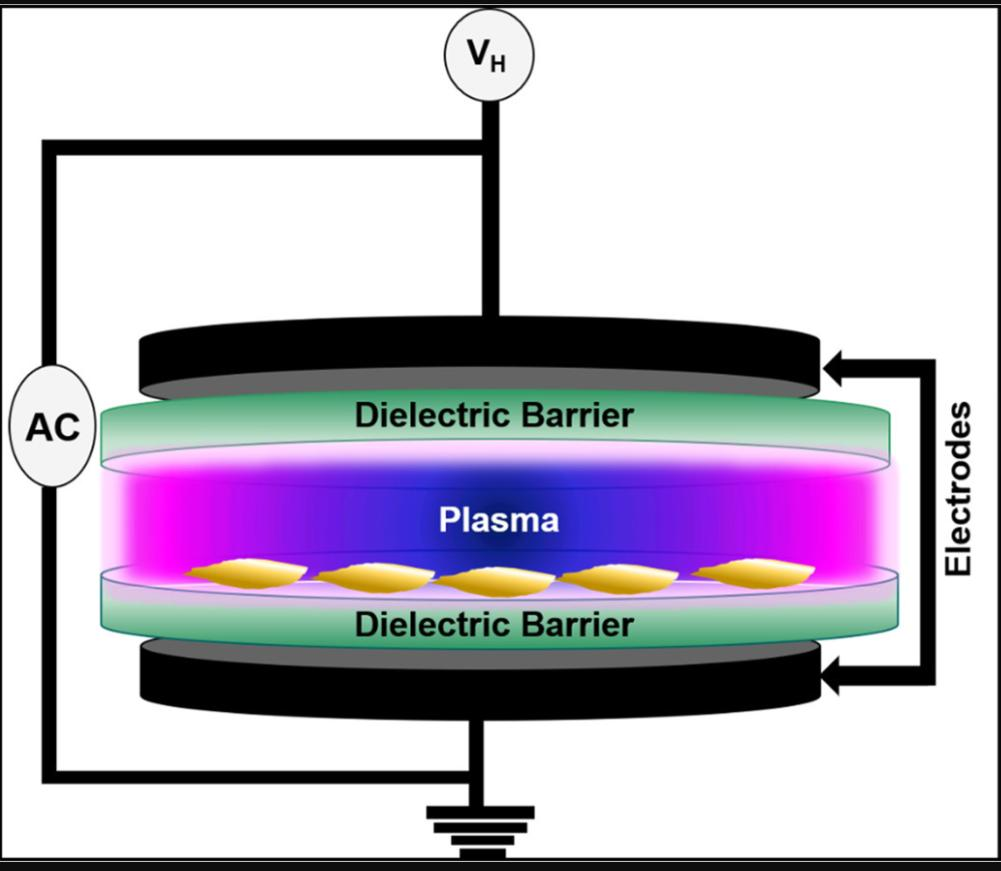

In agriculture, the need for productivity and safety plays an important role. The main agricultural products that can be treated using plasma are cereals and legumes. It is predicted that there will be an 11% increase in the cereal trade by 2032 [Reference 3]. However, the losses due to climate change can threaten the availability of the production. More efficient methods need to be employed to battle deceases impacting the crops and increase the efficiency of production to compensate the losses by climate change. Cold plasma technology is a suitable technology that can help eradicate the deceases in crops and increase the productivity. The main cereal crops that can be treated are wheat, corn and rice. The cold plasma DBD method ensures that the cereal grains exposed are not burned, but they get sterilized as shown in figure 2 [Reference 4].

Figure 2: Exposure of rice grain to cold plasma [Reference 4]

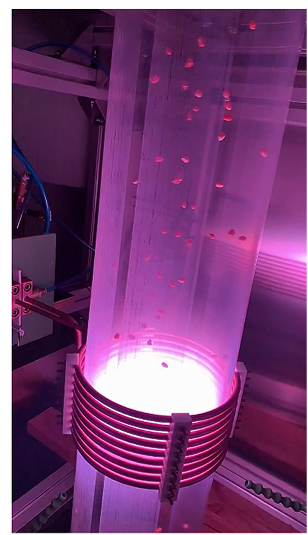

Several research studies have shown that exposure of cold plasma to rice, wheat and corn will improve the seed germination and destroy fungal infections. The cold plasma technology could also be applied to legumes such as peanuts, pea, lentils, green bean and soybean. Other applications are cold plasma treatment of woody plants such as spruce and pine which are the two most abundant coniferous species in Europe. They were also applied to medicinal plants such as hemp and coriander. Figure below shows corn seeds passing through a low pressure inductively coupled plasma [Reference 3].

Figure 3: Exposure of corn seeds to low pressure plasma [Reference 3]

There are several effects that exposure to a plasma inflicts on the seeds that are placed under it [Reference 3]. These are:

· Physical effects

· Chemical effects

· Decontamination from pathogens

· Stimulating plant physiology

Physical effects: One has to make sure that the temperature on the surface does not exceed 60° C or the seed will burn. Studies of seeds under exposure in cold plasma proved that the temperature on the skin was in fact below 60° C. The Scanning Electron Microscope (SEM) studies of the seeds show that exposure to cold plasma will reduce the carbon content and increase the oxygen content so it is basically an oxidation effect.

Chemical Effects: The chemical effects were due to transformation of outer layer due to oxidation and nitration with reactive species. It is basically like an oxidative etching effect. SEM was used to monitor the effect of plasma exposure and it appears that oxidative erosion causes the molecular components of the seed’s coating to be chemically oxidized and removed and hence weigh loss occurs.

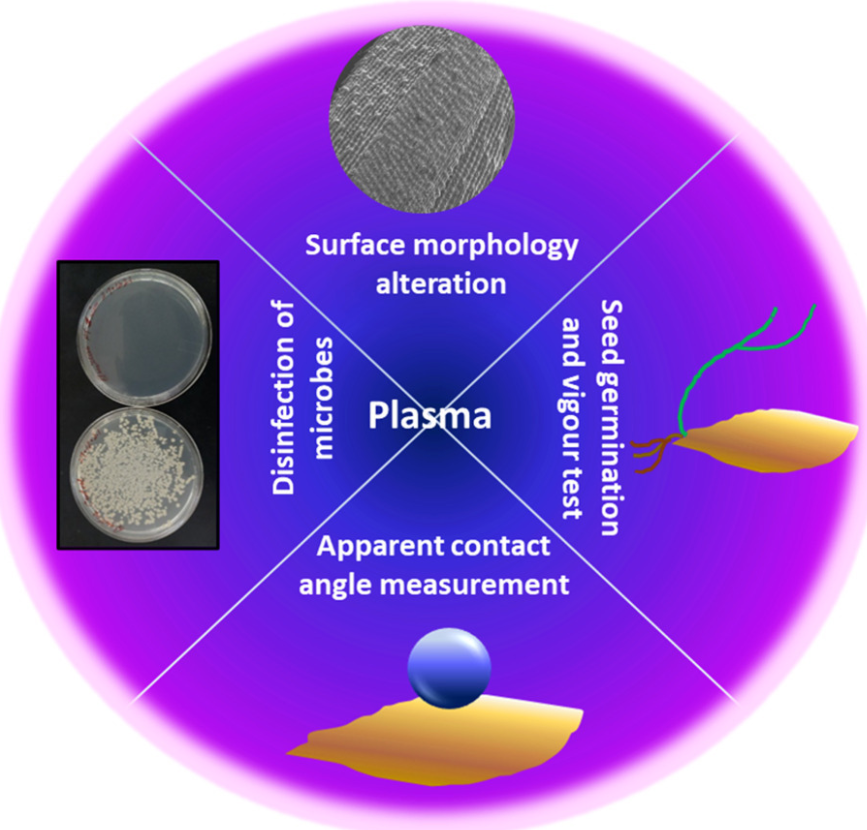

Decontamination from pathogens: Fungal contamination could drastically change seed quality and longevity of seeds. Aside from that, seeds can carry pathogens passively and transmit to growing plants when the conditions are suitable. Cold plasma exposure could sterilize the seed and destroy the fungal infection. However, the efficiency depends on the surface complexity of the seed. If there are crevices and cracks on the surface, the efficiency of the treatment will decrease because the bacteria are protected from plasma exposure by hiding in the cracks. The pic below shows the effect of plasma exposure on seeds [Reference 4].

Figure 4: Useful effects of cold plasma exposure on seeds [Reference 4]

Conclusions: Atmospheric pressure cold plasma technology is promising to improve germination and protecting agricultural seeds from fungal and microbial infections. One challenge is up-scaling the plasma rectors and that can be done by using tiles in the electrodes. The technology is quite promising.

References:

1- Advanced Plasma Techniques: Transforming Industrial Applications

2- Plasma at Your Fingertips: The Impact of Atmospheric Pressure Plasma Jet Technology | Impedans

3- Non-Thermal Plasma as Environmentally-Friendly Technology for Agriculture: A Review and Roadmap, F.Bilea et.al, Critical reviews in Plant Sciences 2024, VOl. 43, nO. 6, 428–486]

4- Dielectric barrier discharge (DBD) plasma treatment for microbial disinfection and enhanced germination in paddy seeds, M. Mukherji et al, Applied Food ResearchVolume 5, Issue 1, June 2025, 100854

Author: Dr Rez Mani PhD